-

Push-in fitting rotatable QSR

- Push-in fitting, rotatable with swivel connection, rotatable by 360° with max. 500 rpm

- Compact installation space

- Connection M5, R1/8, R1/4, R3/8, R1/2, G1/8, G1/4, G3/8, G1/2

- For outside tubing diameter 4, 6, 8, 10, 12 mm

- Threaded connection

- Metric thread with sealing ring

- R thread with PTFE coating

- G thread with sealing ring

- Push-in fittings, self-sealing

- Push-in connectors, self-sealing

- Rotary push-in fittings.

-

Push-in fitting stainless steel NPQR

The sturdy, stainless-steel push-in fitting NPQR has fewer edges where dirt can collect and is highly resistant to most media. This makes it ideal for use in the food industry, as well as in applications in the process industry, battery manufacturing or the automotive industry.

- Very easy to clean thanks to chamfered O-ring and fewer edges where dirt can accumulate

- Optimal price/performance ratio, perfect for applications from a single source

- Maximum corrosion resistance (corrosion resistance class CRC 4 to Festo standard 940 070) and chemical resistance

- High temperature resistance

- Stainless steel

- Operating media: compressed air, vacuum, (water)

- High resistance to chemicals and corrosion

- High resistance to temperature

- Connection M5, M7, G1/8, G1/4, G3/8, G1/2

- For outside tubing diameter 4, 6, 8, 10, 12 mm

- Push-in sleeve: 4, 6, 8, 10, 12 mm

- Threaded connection

- G thread

- push-in fittings

- Plug screw

-

Resistant to media NPQP

Polypropylene fitting NPQP is FDA compliant and highly process-reliable: it is resistant to chemicals, approved for use with food, light and transparent. For the food and beverage industry, biotechnology/pharmaceuticals, medical technology, in cleanrooms and process automation.

- Polypropylene

- Low-cost alternative to stainless steel: resistant to most cleaning agents in combination with tubing PLN

- For use with extreme media influences

- Food grade

- Operating medium: compressed air, vacuum

- Highly resistant to chemicals and corrosion

- Hydrolysis resistant

- FDA compliant

- Inexpensive alternative to stainless steel fittings

- Connection: R1/8, R1/4, R3/8, R1/2

- For outside tubing diameter: 4, 6, 8, 10 and 12 mm

- Push-in sleeve: 4, 6, 8, 10, 12 mm

- Threaded connection

- R thread

- Push-in fittings

- Push-in connectors

- Push-in connectors with push-in sleeves.

- Polypropylene

-

Resistant to welding spatter QS-V0

- PBT, reinforced

- Resistant to welding spatter

- For use in all areas where there is a risk of fire

- Reliable even for applications in close proximity to welding spatter

- Operating medium: compressed air, vacuum, water

- Resistant to welding spatter

- Connection R1/8, R1/4, R3/8, R1/2

- For outside tubing diameter 4, 6, 8, 10, 12 mm

- Threaded connection

- R thread with PTFE coating

- Suitable for vacuum

- Push-in fittings

- Push-in connectors

-

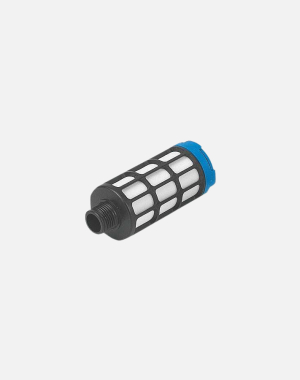

Silencer AMTE

High-temperature resistant silencer in metal with noise level reduction to 71 … 95 dB(A).

- Long or short design

- Metal version

- Slim width

- Operating medium compressed air

- High temperature resistance up to 80°C

- Many different variants

- Universal applications

-

Silencer U

Silencer for reducing sound pressure level to 65 … 84 dB(A).

- Compact design, polymer or die-cast

- Barbed fitting or threaded connection

- Operating medium compressed air

-

Silencer UC

Types of silencers for compact solenoid valves CPE, Compact Performance and for push-in fitting QS, Quick Star.

- For noise reduction and prevention of contamination at exhaust ports of pneumatic components

- Polymer version

- Operating medium compressed air

- For solenoid valves CPE

- Threaded connection or push-in sleeve for push-in fitting QS

-

Silencer UO

Special silencer with outlet opening for vacuum generator VN.

- Special open minimal resistance silencer

- For vacuum generators

- Operating medium compressed air

- Facilitates trouble-free operation of the vacuum generator

- Operating medium compressed air

-

Silencer UOM UOMS

Expandable special silencer with outlet opening for vacuum generator VN for further noise reduction.

- Special open minimal resistance silencer

- For vacuum generators

- Operating medium compressed air

- Facilitates trouble-free operation of the vacuum generator

- Silencer extension for extending the silencer for further noise reduction

-

Silencer UOS-1

Silencer for soft-start/quick exhaust valves MS6-SV of the MS series.

- Silencer for MS6-SV, MS series

- Operating medium compressed air

Authorized Dealer of FESTO / Pneumatic and Electrical Automation