-

Twin cylinder DPZ

Drive with ball bearing guide and high load-bearing capacity thanks to large distance between the piston rods. With fixed cushioning.

- Twin pistons provide twice the force in half the space

- Plain or recirculating ball bearing guide

- Precision stroke adjustment in the end position

-

Vacuum gauge VAM FVAM

Vacuum gauge to DIN EN 837-1 for front panel or in-line installation. With display range to -1 bar / -30 HG.

- Designs based on DIN EN 837-1, available with red-green range

- Pneumatic connection via R or G thread

- Double or single scale

- Display units bar, in Hg, psi

-

Vacuum generator cartridge VN

Vacuum generation in a housing for faster evacuation and higher productivity. This can be done remotely and very compactly thanks to the cartridge VN. Drill a hole in the machine and insert the housingless vacuum generator – ready!

- For fitting into customised housing for decentralised vacuum generation

-

Vacuum generator electropneumatic VN

- Can be used directly in the work space

- Low cost

- With solenoid valve vacuum on/off

- Maintenance-free operation and reduced noise level through an integrated, open silencer

-

Vacuum generator OVEL

The small and lightweight OVEL is perfect for extremely dynamic, decentralised handling applications in the electronics industry. Commissioning and parameterisation are easy thanks to IO-Link®.

- Low-cost, compact vacuum generator

- Light weight

- Various performance levels and vacuum types

- Short switching times thanks to integrated solenoid valves

- Quick, precise and safe placement of the workpiece via the ejector pulse

- Easy assembly

- Minimal installation costs

-

Vacuum generator OVEM

Total process reliability with the OVEM as it monitors set evacuation and ejection times and sends automatic fault notifications. Can be controlled conveniently from the PLC using IO-Link®. The air saving function keeps your compressed air costs to a minimum.

- Compact design

- Monitoring with vacuum sensor with IO-Link®

- Central electrical connection via an M12 plug

- SMaintenance-free operation and reduced noise level through an integrated, open silencer

- Integrated filter with inspection window

- Optionally with air-saving function and LCD display

- Short switching times thanks to integrated solenoid valves

- Adjustable ejector pulse: precise and safe depositing of the workpiece

-

Vacuum generator OVTL

- Ø Module comprising vacuum generators OVEL, the common supply manifold OABM-P and connection accessories. All products are available from the factory fully assembled.

-

Vacuum generator pneumatic VN

- Can be used directly in the work space

- Available as straight type (in-line: vacuum port in line with the supply port) or T-shape (standard: vacuum port at 90° to the supply port)

- Compact and cost-effective

- Maintenance-free operation and reduced noise level through an integrated, open silencer

-

Vacuum Generator VAD VAK

- Sturdy aluminium housing for direct connection of a suction cup

- Vacuum suction nozzle with sturdy aluminium housing for direct suction cup connection

- Nominal size 0.5 … 2 mm

- Port M5, G1/8, G1/4, G3/8.

-

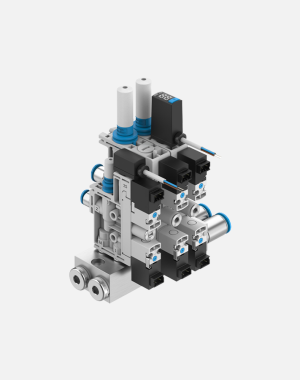

Valve terminal CPV

- Valve terminal type CPV10-VI, CPV10-EX-VI, CPV14-VI, CPV18-VI

- Widths: 10, 14 and 18 mm

- Flow rates: 400, 800 and 1600 l/min

- Diverse valve functions and

- additional functions

- Connection to the CPX electronic terminal via CP interface.

-

Valve terminal CPV

- Valve terminal type CPV10-VI, CPV10-EX-VI, CPV14-VI, CPV18-VI

- Widths: 10, 14 and 18 mm

- Flow rates: 400, 800 and 1600 l/min

- Diverse valve functions and

- additional functions

- Connection to the CPX electronic terminal via CP interface.

-

Valve Terminal CPX CPX-E

- Comprehensive function integration with technology modules

- Installation variants

- Stand-alone as remote I/O

- With valve terminal VTSA-F

- With valve terminal VTSA

- With valve terminal MPA-L

- With valve terminal MPA-S

- I/O modules

- Digital

- Analogue

- Optional CODESYS controller

Authorized Dealer of FESTO / Pneumatic and Electrical Automation