-

Pressure regulator MS-LR-B

- Grid dimension 25, 40, 62 mm

- Competitively priced basic component focused on the most important technical functions

- Lightweight and sturdy thanks to modern polymer materials

- Compatible with the MS series for the ideal combination of low-cost basic functionality and high-end functional requirements

- Stabile control response

- With or without pressure gauge

- Rotary knob with latch

- With integrated secondary exhausting and primary exhausting with return flow function

- MS2: Directly actuated diaphragm regulator

- MS4, MS6: Directly actuated piston regulator

-

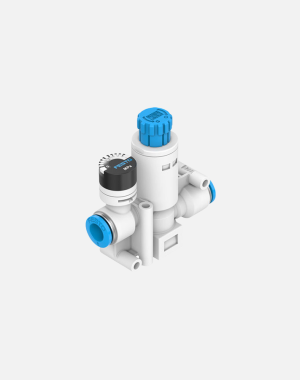

Pressure regulator VRPA

Attractive, compact, strong: our classic in a new design! With VRPA you can quite simply reduce the pressure. The VRPA can be installed directly between 2 hoses, inline, or also directly on the valve terminal. e.g. to save energy when the full network power is not required.

- Regulates the operating pressure independently of the fluctuating inlet pressure

- With secondary exhaust and with return flow function

- Piston regulator with through pressure supply

- Greater energy efficiency thanks to movement-specific pressure adjustment

- Directly actuated

- Available with pressure gauge

- Connections: push-in connector at both ends, thread/push-in connector

-

Pressure regulators for manifold assembly MS-LRB

All compressed air preparation functions: pressure control, switch-on, filter control and soft start valves with safety function, filter, pressure and flow sensors, dryers, water separators, sensors, lubricators and distributors. The right solution for very task. In sizes 4, 6, 9 and 12.

- To build a regulator manifold with through air supply for pressure ranges that can be adjusted independently of one another

- Good control characteristics with minimal pressure hysteresis and primary pressure compensation

- With or without secondary exhausting

- Lockable rotary knob

- Optional pressure sensor and rotary knob pressure gauge

- Integrated return flow option for exhausting from output 2 to input 1

-

Service unit combination MSB4

Perfect compressed air preparation! With its large product range, highly functional components and a wide choice of services, the MS series from Festo offers a complete concept for compressed air preparation – for both standard applications and application-specific solutions.

- Grid dimension 40mm

- Predefined or freely configurable combinations of service unit components

- Depending on the application, combination of filter regulator, filter, lubricator, on/off valve, soft-start valve, branching module

-

Service unit combination MSB4-FRC

With the pre-configured MS series, Festo offers a holistic concept for your compressed air preparation. For simple standard applications as well as for application-specific solutions with the highest quality requirements.

- Grid dimension 40mm

- Filter, regulator and lubricator functions in a single unit

- High flow rate and highly efficient in removing contaminants

- Good control characteristics with minimal pressure hysteresis

-

Service unit combination MSB6

With the pre-configured MS series, Festo offers a holistic concept for your compressed air preparation. For simple standard applications as well as for application-specific solutions with the highest quality requirements.

- Grid dimension 62mm

- Predefined or freely configurable combinations of service unit components

- Depending on the application, combination of filter regulator, filter, lubricator, on/off valve, soft-start valve, branching module

-

Service unit combination MSB6-FRC

With the pre-configured MS series, Festo offers a holistic concept for your compressed air preparation. For simple standard applications as well as for application-specific solutions with the highest quality requirements.

- Grid dimension 62mm

- Filter, regulator and lubricator functions in a single unit

- High flow rate and highly efficient in removing contaminants

- Good control characteristics with minimal pressure hysteresis

-

Service unit combination MSB9

With the pre-configured MS series, Festo offers a holistic concept for your compressed air preparation. For simple standard applications as well as for application-specific solutions with the highest quality requirements.

- Grid dimension 62mm

- Predefined or freely configurable combinations of service unit components

- Depending on the application, combination of filter regulator, filter, lubricator, on/off valve, soft-start valve, branching module

-

Service unit combination MSE6-C2M

Regulating, switching, measuring: complete control of the compressed air supply! The MSE6-C2M monitors the consumption, blocks the compressed air during unproductive times and ensures a soft restart because the pressure never drops below a specific level.

- Grid dimension 62mm

- Intelligent service unit component for optimising the use of compressed air as an energy medium in industrial automation technology

- Combination of fieldbus node, flow sensor, proportional pressure regulator and stop valve with pressure sensor

- Identification of production downtime and leakages

- User-controlled shut-off and pressure regulation

- Configurable rise limit for setpoint pressure

- Equipped with measurement, control and diagnostic functions

- Fieldbus connection (PROFINET IO) via integrated bus nodes enables connection to a higher-level controller

- System extension by extending CPX row 1 interface for connecting an energy efficiency module MSE6-D2M or connecting digital and analogue CPX IO modules

- Two digital inputs and outputs

-

Service unit combination MSE6-E2M

MSE6-E2M constantly monitors the compressed air consumption, blocks the compressed air after waiting a specific period once production has stopped and reduces the system pressure to 0 bar. It can be integrated directly into PROFIBUS, PROFINET, EtherCAT or Ethernet/IP via fieldbus.

- Grid dimension 62mm

- Intelligent service unit component for optimising the use of compressed air as an energy medium in industrial automation technology

- Combination of stop valve, flow sensor, pressure sensor and fieldbus node

- Identification of production downtime and leakages

- User-controlled shut-off and pressure regulation

- Equipped with measurement, control and diagnostic functions

- Fieldbus connection (PROFIBUS DP, PROFINET IO, EtherNet/IP or EtherCAT®) via integrated fieldbus nodes enables connection to a higher-level controller

-

Service unit FRC FRCS

- Filter, regulator and lubricator functions in a single unit

- Size micro, mini, midi, maxi

- Size MICRO, MINI, MIDI, MAXI

- Port M5, M7, G1/8, G1/4, G3/8, G1/2, G3/4, G1, QS4, QS6, also available with NPT thread

- Pressure 0.5 … 7 bar, 0.5 … 12 bar

- Flow rate 110 … 11000 l/min

- Pressure gauge

- With pressure gauge

- Without pressure gauge

- Grade of filtration 40 µm, 5 µm

- Condensate drain

- Manual

- Semi-automatic

- Fully automatic

- Plastic bowl with metal bowl guard

-

Service unit FRC-DB

- Filter, regulator and lubricator functions in a single unit

- With manual or semi-automatic condensate drain

- Size mini

Authorized Dealer of FESTO / Pneumatic and Electrical Automation