-

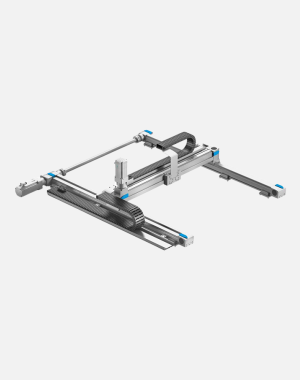

Cantilever system YXCA

- Extremely compact 3D system with attractive price/performance ratio

- Free choice of axial or parallel motor connection for the best use of the installation space

- Pneumatic and electric components can be freely combined

- For horizontal mounting position

- For simple assembly tasks and small parts handling in the electronics industry

- Ideal for use in linear assembly processes or desktop applications

-

Control System CMCA

- Tested and ready-to-install control systems from a single source, in a control cabinet or on a mounting plate.

-

Control system CMCB

- Ready-to-install control system

- Available on a mounting plate with or without control cabinet housing

- Variants with safety functions

- Adapted for balancer kit YHBP

- With connecting cables for balancer kit YHBP connected

-

Linear gantry EXCT

With 90 picks/min, the high-speed-picker EXCT is incredibly efficient. The most dynamic and energy-efficient alternative to conventional serial solutions, it boasts a single-belt kinematic system that greatly reduces dead weight – a benefit that certainly pays off.

- Short cycle times thanks to high dynamic response

- Perfectly matched drive and controller package for quick commissioning

- Especially economical due to the low moving dead weight

-

Linear gantry YXCL

For vertical 2-dimensional movements. Secure and precise thanks to high mechanical rigidity, including for very long strokes of up to 3000 mm in the Y-direction. Configure now and order in just three steps using the Handling Guide Online!

- Ready-to-install complete system including energy chain for cables or tubing as well as suitable motor and servo drive package

- For two-dimensional movements in vertical working areas

- Flexible working area due to scalable strokes in the Y and Z directions

- Choice of vertical axis – pneumatic or electric

- Y-axis based on the toothed belt axis EGC-TB and toothed belt axis with heavy-duty guide EGC-HD-TB.

- Z-axis based on mini slide DGSL (pneumatic), EGSL (electromechanical) and spindle axis EGC-BS (electromechanical)

- High mechanical rigidity and sturdy design

- Ideal for long gantry strokes and heavy loads

-

Linear gantry YXML

High-speed cartesian robot for maximum dynamic response with up to 95 picks/min. It is a highly flexible, compact design including parallel-kinematic actuation. Configure and order now in just three steps using the Handling Guide Online!

- Parallel kinematic drive concept for maximum dynamic response

- Ready-to-install complete system including energy chain for cables or tubing as well as suitable motor and servo drive package

- For two-dimensional movements in vertical working areas

- Flexible working area due to scalable strokes in the Y and Z directions

- Based on linear gantry EXCT

- Maximum dynamic response and efficient operation up to mx. 95 picks/min.

- For rapid processes with high cycle rates like pick & place, feeding parts, stacking, packaging tasks

-

Parallel kinematic system tripod EXPT

Thanks to the high level of integration with CPX and drives EMCA, the high-speed parallel kinematic system doesnot need a control cabinet.

- Low moving mass ideal for demanding requirements on dynamic response in three dimensions

- High path accuracy with a range of path profiles, even for very dynamic operation

- Optional rotary unit as 4th axis, on request with pneumatic rotary through-feed for vacuum or gauge pressure

-

Planar surface gantry EXCH

Maximum dynamic response! The Cartesian high-speed handling unit EXCH can move freely around the entire rectangular working area. Its two fixed motors make it extremely dynamic and provide great acceleration; its moving dead weight is minimal, just like its power consumption.

- Optimal dynamic response when compared with other Cartesian gantry systems

- Drive concept with low moving dead weight

- Flat system design

- High acceleration in both axial directions

- Large working space

-

Planar surface gantry EXCM

Great functionality and a very compact design: the parallel kinematic drive keeps the moving mass low and the footprint small. Its high level of standardisation makes the EXCM-30 an affordable system solution for desktop tasks, e.g. for small parts assembly.

- Excellent functionality in small installation spaces

- Low moving dead weight

- Actuation via two stepper motors with an integrated optical encoder and a two-axis controller

- With recirculating ball bearing guide

-

Planar surface gantry YXCF

High mechanical rigidity and sturdy design for a very wide variety of applications with light to heavy workpieces or payloads and long strokes. Configure now and order in just three steps via the Handling Guide Online!

- Ready-to-install complete system including energy chain for cables or tubing as well as suitable motor and servo drive package

- For two-dimensional movements in horizontal working areas

- Flexible working area due to scalable strokes in the X and Y directions

- X-axis based on toothed belt axis EGC-TB

- Y-axis based on the toothed belt axis EGC-TB and toothed belt axis with heavy-duty guide EGC-HD-TB.

- Especially suitable for very long strokes

-

Planar surface gantry YXMF

High-speed system with very large rectangular working area. A real cost-saving alternative to conventional robotic systems that require 2x SCARA working space. Configure and order now in just three steps using the Handling Guide Online!

- Compact or high dynamic response

- High functionality, extremely compact, flat design and maximum coverage of the working area.

- High-speed system with very large, rectangular working area

- Cost-saving alternative to conventional robotic systems

-

Single-axis system YXCS

- Strokes: max. 3000 mm

- Modules: electric

- Payload: depends on the required dynamics

Authorized Dealer of FESTO / Pneumatic and Electrical Automation