-

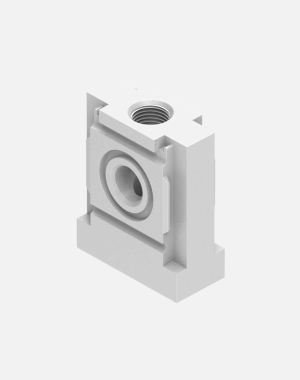

Activated carbon filter LFX

-

- Removal of gaseous oil particles from compressed air using activated carbon

- Air quality class at the output [1.4.1] to ISO 8573-1

- Eliminates odours and vapours

- Residual oil content = 0.003 mg/m³

- Size mini, midi, maxi

- Size 4, 6, 9, 12

- Port G1/8, G1/4, G3/8, G1/2, G3/4, G1, G1 1/4, G1 1/2, G2 also available with NPT thread

- Flow rate 250 … 7090 l/min

- Supply pressure 0 … 20 bar

- Residual oil content <= 0.003 mg/m³

- Plastic bowl with plastic bowl guard

- Metal bowl guard

- Flow direction

From left to right

From right to left.- Prefiltration with 0.01 µm grade of filtration recommended.

-

-

Activated carbon filter MS-LFX

All compressed air preparation functions: pressure control, switch-on, filter control and soft start valves with safety function, filter, pressure and flow sensors, dryers, water separators, sensors, lubricators and distributors. The right solution for very task. In sizes 4, 6, 9 and 12.

- Removal of gaseous oil particles from compressed air using activated carbon

- Air quality class at the output [1.4.1] to ISO 8573-1

- Eliminates odours and vapours

- Residual oil content = 0.003 mg/m³

-

Adsorption dryer PDAD

All compressed air preparation functions: pressure control, switch-on, filter control and soft start valves with safety function, filter, pressure and flow sensors, dryers, water separators, sensors, lubricators and distributors. The right solution for very task. In sizes 4, 6, 9 and 12.

- he adsorption dryer series PDAD is used whenever a pressure dew point of below -20 °C to -70 °C is required. It is ideal for decentralised compressed air drying.

- Adsorption dryers have two cartridges that are filled with a drying agent. Moist compressed air flows alternately through each of the two cartridges, with the water accumulating on the surface of the drying agent. After a specified time, the air flow is switched to the other cartridge and part of the dried air (purge air) is used to regenerate the drying agent in the first cartridge.

- The adsorption dryers PDAD are suitable for use as individual devices and can be integrated in service units of the MS series using the simple modular system of the MS series

- Ideal for decentralised compressed air drying

- Integrated filtering of oil and particulates

- Defined pressure dew point

- Low purge air consumption

-

Branching module FRM

- Outlet at top and bottom

- Can be used as an intermediate distributor for varying air qualities

- Optionally with integrated non-return function and pressure switch

- Size mini, midi, maxi

- Size 4, 6, 9, 12

- Port G1/8, G1/4, G3/8, G1/2, G3/4, G1, G1 1/4, G1 1/2 also available with NPT thread

- Pressure 0 … 21 bar

- Flow rate 1200 … 42000 l/min

- Threaded connection plates

Without threaded connection plates

With threaded connection plates. -

Branching module PMBL

Branching module PMBL can be used as an intermediate branch for different compressed air qualifies and is available with different connections.

- For high-pressure applications

- Food grade see www.festo.com/certificates/PMBL

- Size 90 mm, 186 mm

-

Condensate drain electric PWEA

- Fully automatic condensate drain with independent electric controller

- Interface available for communicating with master control device

- Reliable thanks to contactless capacitive sensor

- Can be used with service units or simply in piping systems

- Ready status and switching status indicated via LEDs and electrical interface

-

Condensate drain, automatic WA

- For attaching to service units and compressed air networks/systems

- Automatic emptying after the max. fill level has been reached

- Automatic emptying after the operating pressure p < 0.5 bar is switched off

- Manual actuation during operation is possible

-

Distributor block MS-FRM-FRZ

All compressed air preparation functions: pressure control, switch-on, filter control and soft start valves with safety function, filter, pressure and flow sensors, dryers, water separators, sensors, lubricators and distributors. The right solution for very task. In sizes 4, 6, 9 and 12.

- Optionally with integrated non-return function and pressure switch

- Outlet at top and bottom

- Can be used as an intermediate distributor for varying air qualities

- Optionally with pressure sensor

-

Energy efficiency module MSE6

- ntelligent service unit component for energy-efficient operation of pneumatic systems.

- Combination of pressure regulator, on/off valve, sensor technology and fieldbus communication

- detection of system downtime by flow measurement

- regulated outlet pressure

- stand-by pressure regulation

- leakage detection

- adjustable regulated pressure rise (soft-start)

- Expandable with CPX system

-

Filter LF

- Good particle and condensate separation

- With manual or fully automatic condensate drain

- Size micro, mini, midi, maxi

- Port M5, M7, G1/8, G1/4, G3/8, G1/2, G3/4, G1, QS4, QS6, also available with NPT thread

- Pressure 0.5 … 7 bar, 0.5 … 12 bar

- Flow rate 110 … 11000 l/min

- Pressure gauge

- With pressure gauge

- Without pressure gauge

- Grade of filtration 40 µm, 5 µm

- Condensate drain

- Manual

- Semi-automatic

- Fully automatic

- Plastic bowl with metal bowl guard

-

Filter regulator LFR LFRS

- Two pressure gauge connections for different installation options

- With manual, semi-automatic or fully automatic condensate drain

- Lockable rotary knob

- Size micro, mini, midi, maxi

- Port M5, M7, G1/8, G1/4, G3/8, G1/2, G3/4, G1, QS4, QS6, also available with NPT thread

- Pressure 0.5 … 7 bar, 0.5 … 12 bar

- Flow rate 110 … 11000 l/min

- Pressure gauge

- Pressure gauge

- With pressure gauge

- Without pressure gauge

- Grade of filtration 40 µm, 5 µm

- Condensate drain

- Manual

- Semi-automatic

- Fully automatic

- Plastic bowl with metal bowl guard

-

Filter regulator LFR-DB

- With manual or semi-automatic condensate drain

- Size mini

- With or without pressure gauge

Authorized Dealer of FESTO / Pneumatic and Electrical Automation