-

Adaptive shape gripper DHEF

$0.00A gripper inspired by nature. It grasps and encloses different types of workpieces and then hands them over, even to people.

- Gripping of parts with undefined positions and shapes

- Form-fitting gripping of products with different geometries

- Form-fitting gripping with suction cup effect

- Gentle gripping of delicate products of varying sizes

RA1 version with robot connection, enables fast integration in lightweight robot

-

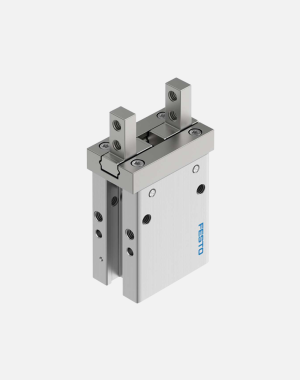

Angle gripper DHWS

$0.00- The standard gripper DHWS is equipped for a wide range of applications and ensures a high gripping force. It has a slotted guide for exterior and interior gripping.

-

- Improved gripper jaw guide

- Internal fixed flow control, does away with the need for external flow control in 90% of applications

- Slotted guide

- Max. repetition accuracy

- Can be used as a double- and single-acting gripper

- Single-acting variant or with gripping force backup, normally closed (NC)

- Suitable for external and internal gripping

- Wide range of adaptation options on the drives

-

-

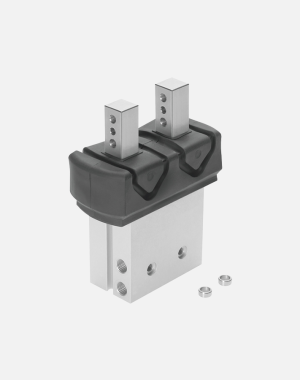

Angle gripper HGWM

$0.00The micro gripper for very tight installation spaces in sizes 8 and 12 and with a gripping torque of 11 … 38 Ncm. Mounting either via clamping flange or male thread.

- Micro gripper: compact, handy design

- Versatile thanks to externally adaptable gripper fingers

- Single-acting gripper, optionally with open (NO) or closed (NC) gripper jaws

- Suitable for external and internal gripping

- Mounting options with clamping flange, with flange mounting, with Z-stroke compensation

-

Bellows gripper DHEB

$0.00For gentle internal gripping of fragile workpieces, the bellows gripper DHEB clamps by adapting to their inner contour.

- 11 sizes for gripping diameter from 8 to 85 mm

- Direction of movement: bellows upwards or downwards

- Different bellows materials: EPDM or silicone

- Air connection on the side or from above

- Optimised process sequence with increased quality: prevents the workpieces from being scratched

- Additional reliability: optional sensing via proximity or position sensor

- For gentle internal gripping of delicate workpieces

-

Parallel gripper DHPC

$0.00- Resilient and precise ball guide

- High gripping force and compact size

- Max. repetition accuracy

- Can be used as a double-acting or single-acting gripper

- Single-acting variant or with gripping force retention normally open (NO) or normally closed (NC)

- Suitable for external and internal gripping

- Wide variety of mounting and attachment options

-

Parallel gripper DHPL

$0.00- High torque resistance due to guided gripper jaw

- Compact and sturdy design

- Ideal for gripping larger parts

- Double-acting piston drive

- Suitable for external and internal gripping

- Mounting: direct fastening via thread, with through-hole

- For position sensing with proximity sensor for T-slot and for C-slot

-

Parallel gripper DHPS

$0.00The oval piston provides the standard gripper with a powerful grip in many application situations.

- Sturdy and precise T-slot guidance of the gripper jaws

- High gripping force and compact size

- Max. repetition accuracy

- Can be used as a double- and single-acting gripper

- Single-acting variant or with gripping force backup, normally open (NO) or normally closed (NC)

- Suitable for external and internal gripping

- Wide range of adaptation options on the drives

-

Parallel gripper EHPS

$0.00The electric gripper EHPS can be used without an external controller. Low noise level.

- Electric version of the pneumatically actuated parallel gripper DHPS

- Ideal for use as a front-end actuator thanks to its low dead weight

- RA1 version with robot connection, enables fast integration in lightweight robot environments

- Controller-free actuation using digital signals

- Gripping force (4 settings) adjustable via ratchet switch or via IO-Link® interface

- RA1 version with robot connection, enables fast integration in lightweight robot environments

-

Parallel gripper HGP

$0.00Self-centring gripper with dust cap for use in demanding environments. External and internal gripping possible.

- High gripping force and compact size

- Self-centring

- With protective dust cap for use in dusty environments (degree of protection IP54)

- Max. repetition accuracy

- Internal fixed flow control

- Versatile thanks to externally adaptable gripper fingers

- Double-acting piston drive

- Suitable for external and internal gripping

- Wide range of adaptation options on the drives

-

Parallel gripper HGPD

$0.00Fully sealed grippers for harsh environments. With exterior and interior gripping.

- Ideal for very harsh environments

- Precise gripping even at high torque load

- Max. gripping force at optimum installation space/force ratio

- 8 sizes with total stroke of up to 40

- Can be used as a double- and single-acting gripper

- Single-acting variant or with gripping force backup, normally open (NO) or normally closed (NC)

- Suitable for external and internal gripping

-

Parallel gripper HGPL

$0.00Sturdy long-stroke gripper for components of different sizes with two parallel pistons moving in opposite directions.

- Space-saving, high forces and torques

- Controlled, precise and centred gripping

- Long stroke: long guide length for the gripper jaws

- Opening stroke can be adjusted to optimise time

- Double-acting gripper with two pistons operating in parallel and in opposite directions

- Suitable for external and internal gripping

-

Parallel gripper HGPM

$0.00Micro gripper in small and handy designs for very tight installation spaces. With flange or clamping flange.

- Micro gripper: compact, handy design

- Versatile thanks to externally adaptable gripper fingers

- Single-acting gripper, optionally with open (NO) or closed (NC) gripper jaws

- Mounting options with clamping flange, with flange mounting, with Z-stroke compensation

Authorized Dealer of FESTO / Pneumatic and Electrical Automation